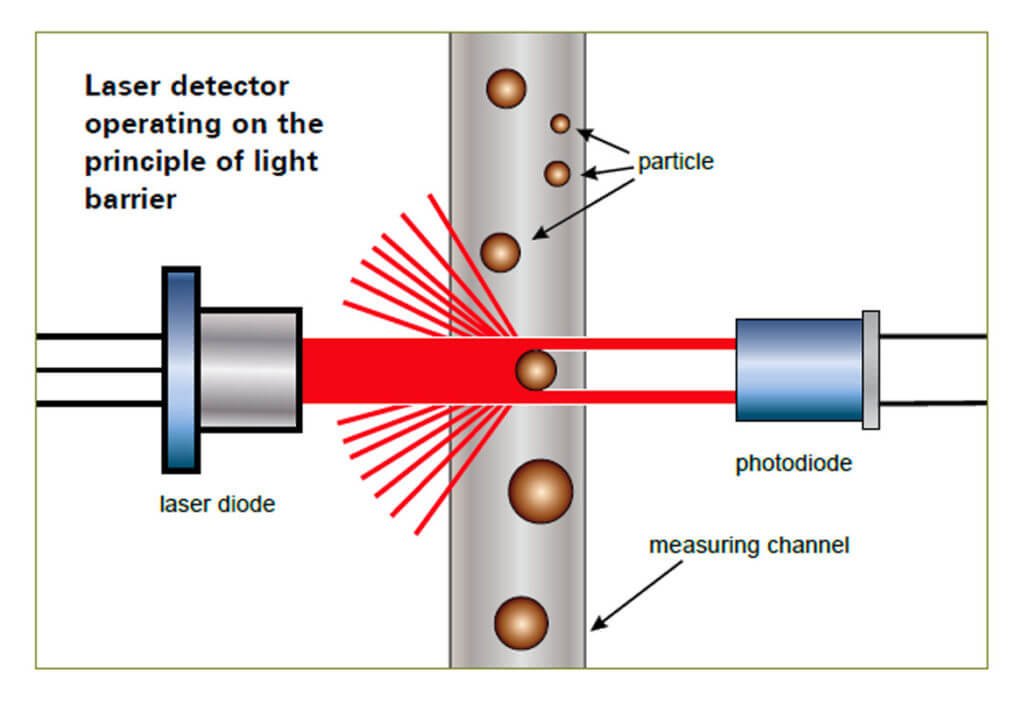

Automatic light blocking particle counters are the most widespread method for analysing the contamination from solid particles in industrial settings.

Automatic particle counters measure the size and passage of individual particles in the fluid flow by the obscuration of the light transmitted by a laser to a sensor/receiver. When a particle crosses the light beam, the intensity of the light received by the sensor/receiver is reduced proportionally to the size of the particle. The Signal is transmitted to a processor that interprets the size and number of the particles, expressing it via ISO 4406 code.

The automatic counters measure not only the level of contamination but also the percentage of water RH% dissolved in oil.

Water is the most common contaminant and attacks systems as follows: Corrosion of the metal caused by water, degradation of the fluid with precipitation of additives and oxidation of the fluid, decrease in lubricant thickness and therefore it should be constantly monitored.

It is possible to integrate automatic counters with sensors able to establish the ageing conditions of fluids and assess the types of mixtures in oil by measuring and detecting changes in viscosity, temperature and electricity.

Rapid response to changes in the work parameters assures the rapid implementation of corrective actions.

products menu

▽