The mobile and fixed filtration units are used on the external circuit of the tank

MOBILE UNITS

DELTA ZETA PAK

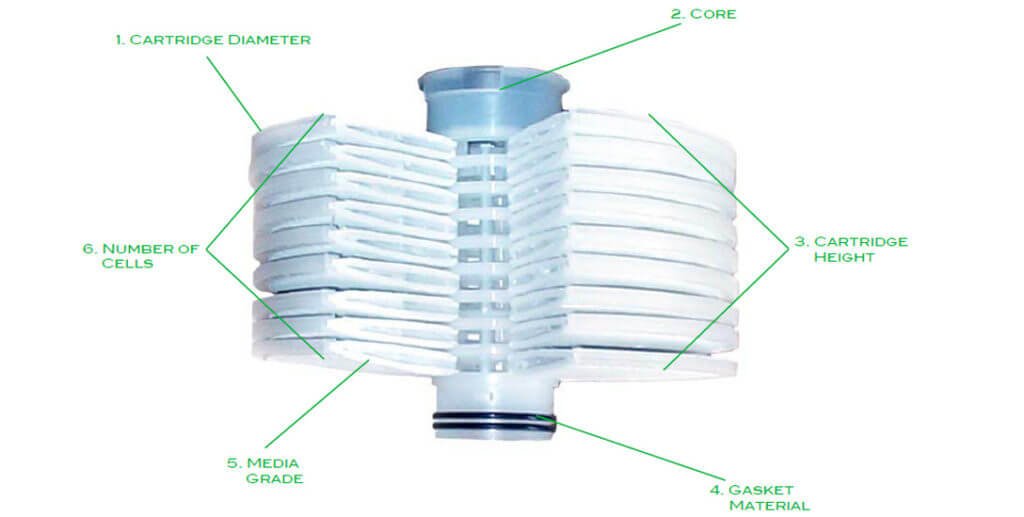

The DELTA ZETA PAK mobile and/or fixed units use lenticular depth filter elements. The available flow rates are 5-10-15-20 L/min.

The absorption of the filter media of the depth filters and the low flow rate make it possible to efficiently remove both “hard” contaminants and “soft” contaminants (sludge), as well as the products in varnish caused by thermal degradation and oxidation of the fluid. The filter elements also stabilise the ideal level of contamination and keep it constant even during heavy-duty use.

The elements have a large filtering surface and an excellent capacity for retaining contaminants, and so can be used for a long time before they get clogged and need to be replaced, making the DELTA ZETA PAK unit both versatile and cost-effective. Thanks to a patented removal system, the elements of the depth filters can be replaced quickly and in a simple and safe manner when clogged.

DELTA ZETA DRI PAK

The mobile or fixed DELTA ZETA DRI PAK version with flow rates of 5 to 20 L/min uses filter elements that can remove both solid contaminants and free water.

DELTACART 5000

The DELTACART filter units have pleated particle filter elements with a large filtering surface and a removal capacity of 5, 7, 12 and 22 um βx>1000. The choice of filter element depends on the class of contamination to be attained.

DELTA BS

- Machining

- Lapping machines

- Grinding

- Washing systems

- Recovery of contaminated oil

DELTAHANDLE PORTABLE UNIT

OIL PURIFIERS

DELTAFLUID OPD purifier systems are designed for use in a wide range of viscosities, from transformer oils to lubrication oils (ISO VG 680). They remove water in the system in the three conditions: free and emulsified (100%) and dissolved (up to 90% of the saturation point); they remove dissolved gases and solid contamination up to a cleanliness level of ≤ ISO 4406 16/13/10. The level of cleanliness depends on type of filter element (removal power) used.

products menu

▽